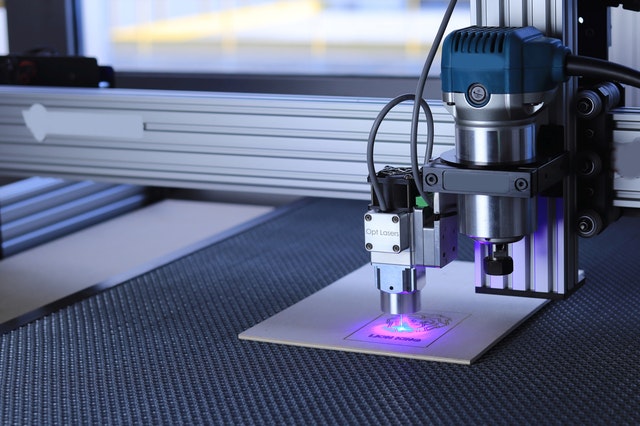

10 Mar Pros and Cons of Desktop Laser Cutter

Modern manufacturing is benefiting from desktop laser cutters today. Besides metal, these devices cut through many other materials and have become quite essential in the modern sheet metal industry. Before the invention of lasers, most shops sheared and punched on flat materials to create workpieces. Punching and shearing were not as reliable to perform complex tasks. That is why when the desktop laser cutter came to be, most shops rejoiced and welcomed it with both hands.

This way of cutting is a way more advanced method of operations. It is a noncontact action that doesn’t require force applied to the raw materials. What’s more, these segments don’t need deburring.

What can a desktop laser cutter cut?

This process is a popular activity in the world today. Its popularity is largely centered on how versatile it is. This means the devices cut through various materials discussed below. Read on to find out the materials suitable for a desktop laser cutter to cut.

Metals

As versatile as these devices can be, they can cut through all metal types. These include mild steel, stainless, and non-ferrous metals, among others. However, reflective metals prove complex for a desktop laser cutter. In this case, fiber beams are used instead.

A device like this can cut through metals ranging up to 30mm thickness. However, the maximum thickness a machine can handle depends on its ability and service. The variation is centered on the beam’s power and the skills of the operator.

Wood

A desktop laser cutter can also cut through several types of wood, including MDF and plywood. The oils and resin in the wood may pose a fire threat. Therefore, you should exercise precaution.

Plastics

All forms of transparent plastics leave a beautiful appearance after being cut by a desktop laser cutter. These include acrylic, Lucite, and PMMA, among others. The beam melts the edges of the plastics to ensure they appear polished.

Cardboard and paper

Ever wondered how invitations card are decorated intricately? They use a device to make complicated designs on paper and cardboard.

POM

The engineering industry widely uses POM plastic. It is mainly used for making gears and sliding and guiding elements. Additionally, POM is used to make some medical instruments and food packaging items. It uses these machines to create patterns and designs.

Advantages of a laser cutter

Flexible

You don’t need to exchange tools while using a machine like this. This process only requires the same setup to cut through various shapes sharing the same thickness. It is also ideal for complex cutting.

Accurate

Many people go for this process because it produces the most accurate cuts. Compared to other thermal cutters, a machine like this provides the utmost precision, creating fine-looking items.

Replication

This process produces items similar to the intended look.

Fast

Other mechanical cutting methods don’t hold a candle to this process in terms of speed. This is especially true on complex cuts.

Quality

Desktop laser cutters leave high-quality cuts that require little to no deburring. The material and its thickness will determine the quality of the cuts.

Versatile

As mentioned, these devices are more versatile as they cut different materials. The same machine is designed to perform various tasks. Besides cutting, the machines also mark items.

Downsides of this process

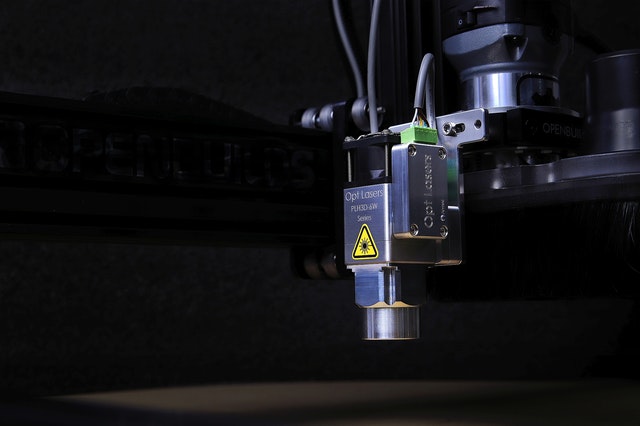

Requires expertise

Before operating a desktop laser cutter, you need to have sufficient knowledge. It requires a specialized operator to ensure the proper setup of the machine to produce superior quality cuts.

Produces dangerous fumes

When cutting through various materials, a machine causes them to melt. It, in turn, emits gasses and other harmful fumes to the surrounding. This is particularly true when cutting through plastic materials.

Sorry, the comment form is closed at this time.